Product Tooling Inc. is marking its 50th anniversary in Sunbury.

To be more precise, it’s in Kingston Township at 4290 North 3 Bs and K Road near state Route 521. However, it has a Sunbury mailing address.

The Delaware Gazette did a profile of the company for its 20th anniversary in 1968, whose yellowing page hangs in the firm’s office. So it is only fitting that Product Tooling is profiled again at a half-century.

President Rodney Harp said Product Tooling has spent all 50 years on the family farm in rural Sunbury, and is a three-generation family business that employs six and an apprentice. His father, Robert L. Harp, founded the company after working at machine and tooling companies in Delaware. His son, Kurtis Harp, is introducing the company to new practices, such as a demonstration video. Each generation has the same enthusiasm for their work.

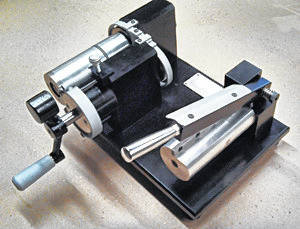

Product Tooling is a custom shop that fabricates parts. Although cramped, the building has milling machines, lathes, CNC machine, welding machine, surface grinder and other machinery. In addition to its equipment, the shop’s employees use their heads to develop one-of-a-kind items.

“We work mainly for industries all around to provide them with tooling and parts that they need,” Rodney Harp said. “But we do farmers and neighbors, try to help everybody out. Being a job shop, our specialty is one of this, two of that. We don’t do thousands of anything really. We have pieces we make a couple hundred of, but that’s an exception.”

That means they might make one part for a client, and then maybe the same in another six months. Among the products they’ve made include robotic hands, plates to keep volleyball poles upright, automotive parts and can trimmers. The Harp family is protective of its client base, but suffice it to say the family’s customers are both near and far away.

”We enjoy working with our hands and actually making something,” Rodney Harp said. “Creating something with your hands, it’s almost an art where you have to visualize chunks of steel when you want this done what it’s going to look like and how you’ll get there. You’ve got to cut away everything you don’t need.”

He added the shop was pretty busy when a visitor walked in a couple months ago.

“You never know what’s going to come in the door here, or when. The work here changes when the phone rings or an email. We need this tomorrow, or we’re quoting a job.”

One New Year’s Eve, the employees worked all night in order to deliver a part. Recently, the phone rang on a Thursday and they had to work on a Saturday to have an item for a customer on Monday.

“That’s what the business is about, our customers. It’s not about us,” Rodney Harp said. “We’re here to serve our customers. If they need something, we’ll make it, if we can. There aren’t too many things we can’t — challenge us.”

Rodney’s wife, Beth Harp, serves as Product Tooling’s secretary and treasurer. She also transports the finished product to customers.

“I call myself the gofer,” Beth Harp said. “I married into the business in 1991. He’s (her son, Kurtis Harp) the future, the next 50 years of the company.”

“I grew up in the truck as she made deliveries,” Kurtis Harp said.

Product Tooling’s vice president and webmaster, Kurtis Harp has an agricultural engineering degree from The Ohio State University.

“It’s not for everybody,” he said of the work. “You have to be a little obsessive-compulsive. Precision is important. A few thousandths of an inch can make an impact.”

Sometimes, they’ll turn away business. Someone may request a part, and if it’s common enough to get cheaper at the hardware store, they’ll advise them to go down the road.

As for the future, Kurtis Harp said Product Tooling is looking at possibly adding more floor space, upgrading or adding equipment.

“We pride ourselves on making the extra step,” Kurtis Harp said. “For example, we weld something and then we clean it up, touch it up with paint — go the extra step to make sure it goes out right. We take pride in our work. It’s not mass-produced. We build each piece.”